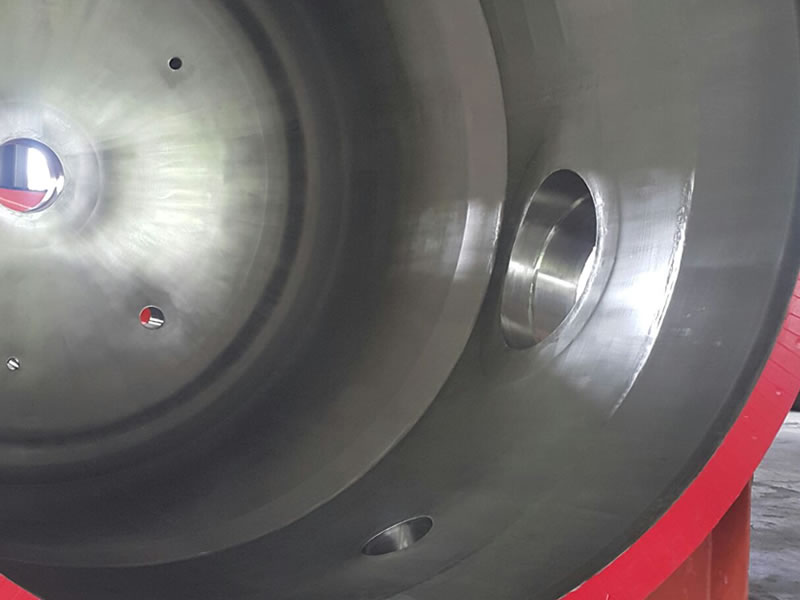

Mechanical polishing covers grinding, buffing, and polishing – all processes for improving the surface conditions of a product for decorative or functional purposes. The various techniques are abrading operations although some plastic working of the surfaces may occur, particularly during buffing.

The process is to do grinding first, polishing second, and buffing third. In general, grinding permits far more aggressive abrading action than polishing. Likewise, polishing is a far more aggressive abrading action than buffing.

In grinding, polishing and buffing, labor is a major variable in the process. The requirement if for highly skilled labor with years of experience and a thorough knowledge of the art of their craft.

The basic mill plate and sheet metal finishes for stainless steel include five grades that have finishes that are produced mechanically by using abrasive compositions and buffing wheels.

Special mechanical polishing procedures are required for preparing metal surfaces, such as stainless steel, for electropolishing. Please look at the comparison table and compare the various polished mill finishes against, the abrasive grit number used to produce them, and the surface roughness readings before and after electropolishing.